Project Assignment on Hydroformylation of Alkenes and Mechanistic Investigation

Wednesday, April 15, 2020

Comment

CONTENT

- Introduction

- Importance of hydroformylation

- Various catalysts employed in hydroformylation reaction

- Cobalt Catalysts for Hydroformylation-

i.

Catalytic cycle using HCo(CO)4

ii.

Disadvantages of cobalt carbonyl complex catalyst

iii.

Phosphine Modified Cobalt Catalysts

iv.

Steric effect of PR3

- Rhodium – Phosphine Catalysts

i.

Catalytic cycle using HRh(CO)(PPh3)3

catalyst

ii.

Drawback of HRh(CO)(PPh3)3

catalyst

- Factors Affecting the n/iso Ratio of Hydroformylation Products

- Water-soluble rhodium catalysts

- Bidendate Phosphine Rh Catalyst

- Other Aspects of Hydroformylation

- Enantioselective Hydroformylation

- Conclusion

- Bibliography

Experimental setup with reactor system

INTRODUCTION

In 1938, Otto Roelen discovered the

hydroformylation – often called the oxo process, one of the first commercially

important homogeneous catalytic reactions. He found that a Cn alkene can be converted to a Cn+1 aldehyde by the addition of H2 and CO to an olefinic double bond catalyzed by

cobalt or rhodium carbonyl complexes.

In simple terms, the equation can be written as

Aldehydes produced by hydroformylation are usually

reduced to alcohols that are used as solvents plasticizers and in the synthesis

of detergents.

IMPORTANCE OF HYDROFORMYLATION

The reaction was first discovered

by Otto Roeln at the Ruhrchemie industry in Germany while studying recycling of

olefins. Since then, the reaction has been developed by industry and account

for more than 7 × 106 tons/year

of aldehydes. It is one of the largest homogeneous catalytic process worldwide.

Actually, aldehydes are not the end product,

they get further reduced to alcohols; sometimes in the same plant or by other

heterogeneous catalysts. The short chain alcohols thus obtained are extensively

used as solvents in the lacquer industry for making plasticisers and the long

chain alcohols are used in the manufacture of synthetic detergents.

As the alkene also has equal

propensity to react with H2, it is interesting to study the thermodynamics

involving both hydrogenation and hydroformylation reactions. The changes are in

entropy and the free energy of these two reactions for propene under standard

conditions are given below.

CH3CH=CH2 + CO + H2

→ CH3CH2CH2CHO

∆H = -150 kJ/mol

CH3CH=CH2 + H2 → CH3CH2CH3

∆H = -126 kJ/mol; ∆G = -88kJ/mol

It becomes evident that the alkane is the

thermodynamically favoured productand not the aldehyde. Since the aldehyde is

the major product, the entropy loss is more important and ∆G becomes less

negative. Also, the reaction is exothermic and if conducted under adiabatic

conditions, the temperature rises and ∆G becomes close to zero.

VARIOUS CATALYSTS EMPLOYED IN HYDROFORMYLATION REACTION:

1) Cobalt Catalyst: HCo(CO)4

2) Cobalt Phosphine-Modified Catalyst: HCo(CO)(PR3)3

3) Rhodium Phosphine Catalyst: HRh(CO)(PPh3)3

4) Aqueous phase Rhodium Catalyst: TPPTS

(Triphenylphosphinetrisulfonate)

5) New generation of Rhodium Catalyst: bidentate

phosphine ligands

Over the years, four catalytic processes have come into

prominence for hydroformylation reaction. These are:

·

The Co2(CO)8

catalysed process,

·

The Co2(CO)8/PR3 catalysed

process,

·

The HRh(CO)(PPh3)3 catalysed

process and

·

The biphasic HRh(CO)(PR3)3 process

(R = m- C6H4SO3Na)

The major difference between these processes are-

The major difference between these processes are-

- The operating temperatures and pressures,

- The ratio of the product formed, n-aldehyde (n/iso ratio),

- The rate of reaction and the control of side reactions such as hydrogenation and

- Ease of recovery of catalyst.

Currently C3

to C15 aldehydes are produced by the oxo process and the are

subsequently converted into amines, carboxylic acids and most importantly to

primary alcohols.

Some of the major industrially important end

products are butanol, 1,4-butanediol ( for THF synthesis), vitamin A and 2-

ethylhexanol. 2-Ethylhexanol is used in making diethylhexyl phthalate

(DEHP),also lnown as dioctyl phthalate(DOP),which is the most widely used

plasticiser in the world.

COBALT CATALYSTS FOR HYDROFORMYLATION:

Cobalt

catalyste dominated the hydroformylation industry till the early 1970s after

which the triarylphosphine rhodium based catalysts took over.The latter are

especially good with C8 or lower alkenes when a higher selectivity

of the linear aldehyde is required. Under H2/CO pressure, cobalt

salts produce HCo(CO)4 as the active catalytic species.

The most widely

accepted mechanism for the catalytic cycle for cobalt based catalyst Co2(CO)8

was proposed by Heck and Breslow in 1961.

Kinetic

studies support a general rate expression as given below:

d[aldehyde]/dt

= k[alkene][Co][pH2][pCO]-1

- Inversely proportional to CO concentration because CO dissociation from the coordinatively saturated 18e- species is required

- Using a 1:1 ratio of H2/CO, the reaction rate is independent of pressure

- HCo(CO)4 is only stable under certain minimum CO partial pressures at a given temperature

- CO pressure ↑ → reaction rate ↓ & high ratio of linear to branched product

- CO pressure ↓ → reaction rate ↑ & branched alkyl ↑ (reverse ß-elminination)

Catalytic cycle using HCo(CO)4:

In the

catalytic cycle, the general catalyst is 16-electron, four coordinate Co1 comples,

HCo(CO)3. This species is not readily available, instead catalytic

precursor Co2(CO)8 is introduced that form HCo(CO)3 under

reaction conditions.

For this

catalytic cycle, Co2(CO)8 and H2 introduced

that form HCo(CO)4( an 18 electron species) which then lossesa CO to

give HCo(CO)3 (a 16 electron species) and creates a vacant coordinatin

site required for alkene.

The alkene coordinates

to this vacant site to form an 18-electron complex whic undergoes migratory

insertion of the olefin into the C-H bond and therefore, another 16-electron

complex having vacant coordination site is formed.

A CO ligand

is then coordinated to the vacant site to form RCH2CH2Co(CO)4

complex. Now insertion of a CO ligand of

RCH2CH2Co(CO)4

occurs into the alkyl-cobalt bond to give the acyl-cobalt complexRCH2CH2CO-Co(CO)3.

The reactant H2 is added oxidatively to the coordinatively

unsaturated cobalt-acyl comlex to give a Co(III) complex which finally

undergoes reductive elimination of product, RCH2CH2CHO

and regenerates the active catalyst HCo(CO)3.

The general

relative reactivity of alkenes for

hydroformylation is as follows:

Disadvantages of cobalt carbonyl complex catalyst:

·

It operates at high temperature (140 – 175oC)

and high pressure (200 – 250 atm.).

- Straight chain(n -) as well as branched chain (iso -) aldehydes are formed. The n:iso ratio is found to be 3:1 which is not a good ratio.The n:iso ratio should be high because straight chain aldehydes are more biodegradable than the branch ones.

Phosphine Modified Cobalt Catalysts:

The addition

of PPh3 ligands to the cobalt carbonyl catalyst brought about a

dramatic change in the rate of the reaction and its regioselectivitydue to electronic and steric effect of substitution of PR3. When a CO is

substituted by the electron donating PR3 group, the back donating

from the metal to the rest of the CO group increases, thereby increasing the

thermal stability of the catalyst against decomposition.If R=Bu, the n/iso

ratio is ( 9:1 ).

Steric effect of PR3:

Bulky PR3 group influences the insertion

direction of alkene to Co complex and geometry of intermediate (favors

Anti-Markovnikov; Hydrogen transferred to carbon with bulkier R group).

The CO

partial pressure required to stabilise the catalyst comes down considerably

from 200–300 to 50–100 bars. Also, the hydridic nature of hydrogen increases as

there is more electron density on the metal. The catalyst can even convert the

aldehyde formed to alcohol by hydrogenation, but the presence of less electron

donating phosphines like PPh3 on the catalyst checks this process

and produces less of the alcohol.

A highly

active catalyst has as additional drawback since it also hydrogenates the alkene

and some alkene is wasted in the formation of unwanted products. Higher stabliity

of the catalyst also means lesser activity.

RHODIUM – PHOSPHINE CATALYSTS:

In 1965,

Osborn, Wilkinson and others reported that Rh(I) catalysts with PPh3

affect not only hydrogenation but also hydroformylation with high

regioselectivity near ambient conditions. As halides were found to be

inhibitors for hydroformylation, the original Wilkinson’s catalyst was modified

to contain no halides. HRh(CO)(PPh3)3 and Rh(acac)(CO)2

are two commonly used catalyst precursors for hydroformylation.

The catalytic

cycle shown that the step are analogous to Heck’s mechanism for

hydroformylation using HCo(CO)4. Kinetic studies on the rhodium

catalyst showed that unlike the cobalt catalyst, there is no inverse dependence

of the rate on CO concentration.

Rate α

[propylene][Rh][pH2]

Drawback of HRh(CO)(PPh3)3 catalyst:

The main

drawback of Rhodium – PPh3 catalyst is a problem related to the

industrial process. Since a high temperature is required for separation of the

long chain aldehyde products, the catalyst decomposes at that temperature. So

the application has been limited to C3

and C4 alkenes.

This problem

was solved by using a water soluble phosphine along with the catalyst and also

by resorting to biphasic catalysis.

Catalytic cycle using HRh(CO)(PPh3)3 Catalyst :

Tables 1 and 2 summaries the

reaction parameters of four catalysts and their advantages and disadvantages

Table 1: Reaction parameters and n/iso

ratio obtained with different catalysts

Catalyst (active form)

|

Reaction parameters

|

(n/iso) ratio maximum

|

Co2(CO)8

[HCo(CO)4]

Co2(CO)8/PR3

R = n-Bu and other similar groups

HRh(CO)(PPh3)3

|

Pressure 200-300 bar

Temp. 110-160oC

Cat. Concentration* 0.1-1.0

Pressure 50-100 bar

Temp. 160-200oC

Cat. Concentration* 0.6

Pressure 15-25 bar

|

3:1

7:1

16:1

|

HRh(CO)(PR3)3

R = mC6H4SO3Na

|

Temp. 80-120oC

Cat. Concentration* 0.01-0.05

Pressure 15-25 bar

Temp. 80-120oC

Cat. Concentration* 0.01-0.05

|

19:1

|

*percentage of

metal/olefin

Table 2: Advantages and disadvantages of

various hydroformylation catalysts

Catalyst (active form)

|

Advantages

|

Disadvantages

|

HCo(CO)4

Co2(CO)8/PR3

R = n-Bu and other similar groups

HRh(CO)(PPh3)3

HRh(CO)(PR3)3

R = mC6H4SO3Na

(water soluble), biphasic catalysis

|

Relatively less alkene hydrogenation(< 2%).

Catalyst decomposition redused due to increased thermal stability of

catalyst.

Better n/iso selectivity due

to increased hydritic character of H.

Low pressure (15–25 bar) aand low temperature.

High n/iso ratio selectivity

(94%)

Easy catalyst recovery and less loss, low catalyst concentration

required.

Less olefin

|

Thermal instability and volatility of (HCo(CO)4 leads to the

deposition of Co or its oxide on the reactor. High pressure of CO (200-300

bar) required to prevent this brings in operational difficulties.

Rate of reaction α 1/[CO].

So, increase in CO pressure reduces rate.

Low n/iso ratio

Pressures and temperatures still on the higher side.

Lower reaction rate (at 180oC, the rate is only 20% of the

rate of HCo(CO)4 operating at 145oC).

Increased hydrogenation of alkenes (up to 15% loss of alkenes).

Good for production of 2-ethylehexanol from propylene (up to 85% yield

in a single reactor).

Applicable only to C3 and C4 olefins as catalyst

is thermally unstable at the high temperatures required for the removal of

products by distillation.

High cost of Rh in comparison to Co.

Low rate of reaction due to reduced miscibility to higher alkenes with

the aqueous phase of catalyst.

Pressure required is on the higher side

|

hydrogenation(< 2 %).

Applicable to long chain olefins as well

|

in comparison to HRh(CO)(PPh3)3.

|

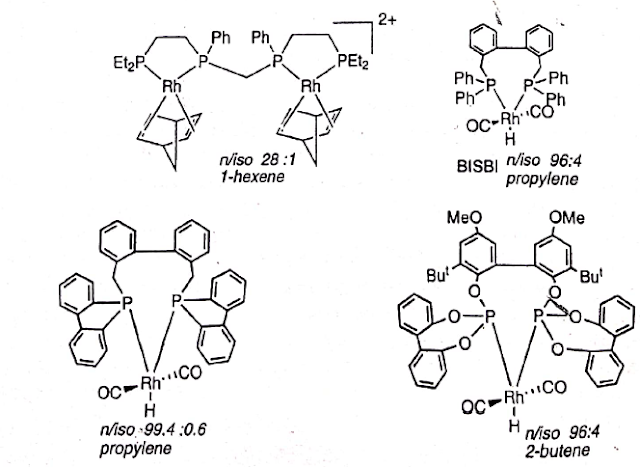

FACTOR AFFECTING THE n/iso RATIO OF HYDROFORMYLATION PRODUCTS:

One of the

directions of recent research in hydroformylationreactions has been to improve

the n/iso

ratio of aldehyde products.The first major development was the discovery of

a chelating biphosphine BISBI developed by Eastman

Kodak..

For example,

Rh with BISBI as ligand gave an n/isp ratioof

96:4 under mild condition. Studies on related biphosphines led to an even

better n/iso ratio; for example, when

PPh3 groups in BISBI were replaced with dibenzophosphole units, it

resulted is an n/isp ratio of

99.4:0.6. However, there was a problem with the catalyst stability.

Piet van Leeuwen and coworkers carried out

systematic studies on a series of biphosphines by varying their bite angle.

They observed that larger natural bite angles in the vicinity of 120o

favoured a higher n/isp ratio of

hydroformylation products.

The use of

phosphites as ligands instead of phosphines also led to a higher n/iso ratio. The percentage of linearity

obtained for PPh3 and P(OPh)3 is very similar at low

ligand concentrations. However, at higher ligand concentrations, phosphites

give a better n/iso ratio of

products. The electronic and steric effects of the substituents on the phosphites

play a significant role in deciding the rate and selectivity of the reactions.

One major finding from a comparative study is that higher the χ value of the

phosphine/phosphite, higher the selectivity towards linear products.

Table 3 gives

some examples indicating this observation. Based on these two findings, a

series of biphosphite ligands having large bite angles were prepared and found

to be useful for realising a high n/iso

ratio of hydroformylation products.

Table 3: Product selectivity in

hydroformylation with rhodium phosphite and phosphine catalysts for 1-heptene

at 90oC temperature and 7 bar pressure of CO/H2.

R3P:R =

|

χ value

|

Linearity of product(%)

|

Ph

PhO

n-Bu

n-BuO

4-Cl-C6H4O

CF3CH2O

|

13

29

4

20

33

39

|

82

86

71

81

93

96

|

WATER-SOLUBLE RHODIUM CATALYSTS:

Ø Water soluble catalyst are made using sulfonated PR3 ligands (3,3′,3″-phosphanetriyltris(benzenesulfonic acid) trisodium salt; TPPTS)

Ø Runs at mild conditions (at 18 bar and 85- 90°C)

Ø Easily separated because water-soluble catalystsremain in aqueous phase and aldehyde is separated into organic phase with higher regioselective ratio between linear and branch.

BIDENDATE PHOSPHINE Rh CATALYSTS

The present invention relates to a bidentate

phosphine ligand, a phosphine phosphorus atom connected by a bridge group, the

bridge group bidentate phosphine ligand containing one ortho position by two

aryl groups fused ring system consisting of, an aryl group which are connected

by two bridges, the first bridge with a -O- or -S- atom composed of a second

bridge containing one oxygen, sulfur, nitrogen, silicon or carbon atom or a

combination of these atoms one group, the two phosphorus atoms linked to two

aryl groups in the ortho -O- or -S- atom of a bridge. This also relates to

bidentate phosphine ligand containing catalyst systems for further one kind of

a transition metal compound, this system can be used for thehydroformylation.

In Rh-catalyzedhydroformylation, the n:iso ratio increases with the bite

angle = (preferred P–M–P angle) of a chelate phosphine, probably because

these ligands facilitate the RE step in the mechanism. The Rh complex (9.27) of

the wide bite angle ligand, BISBI, has proved particularly useful.Ø Over the past 20 years, research was focused on bidentate ligands because of remarkably increased regioselectivity between n/iso ratio of aldehydes.

Ø High regioselectivity is the related to the

stereochemistry of complex combined with the electronic and steric factors of

bidendate PR3.

OTHER

ASPECTS OF HYDROFORMYLATION: The overall effectiveness of other metals are

compared with Co and Rh.

Rh > Co >Ir> Ru >Os>Mn> Fe >

Cr, Mo, W, Ni, Re

Rel. Reactivity: 104-103 1

10-1 10-2 10-3 10-4 10-6< 10-6

ENANTIOSELECTIVE HYDROFORMYLATION:

Enantioselective

hydroformylation is a relatively recent development in hydroformylation

reactions. It is interesting to note that chiral aldehyde will be formed only when

the addition of H2/CO to the alkene occurs in the Markownikoff

manner. In contrast to normal hydroformylation, a better n/iso ratio is preferred in enantioselective hydroformylation as

the n isomer will be nonchiral. Initially,

platinum based catalysts were tried; however, these gave poor n/iso ratio and were plagued by

hydrogenation. The isomerisation of the alkene also occurred.It is interesting

to note that hydroformylation in the Markownikoff sense will form only the chiral

aldehydes.

Rhodium based

chiral catalysts such as HRh(CO)2(R,S)-BINAPHOS have been developed

which give high n/iso ratio as well

as good enantiomeric excess.

CONCLUSION:

· Through the

catalyzedhydroformylation reaction, olefins are converted into aldehydes;

mechanism and corresponding energy calculation were demonstrated.

· The different type of phosphine ligands and

cobalt- and rhodium-based catalysts were introduced; bidendate phosphine Rh

catalyst showed the highest ratios of linear to branched aldehyde even at

ambient conditions.

· Enantio- and

regio-selectivity can be increased if specifically designed ligands on Rh§ catalysts are used

BIBLIOGRAPHY

- B D Gupta and A J Elias, Basic Organometallic Chemistry

: Concepts, Synthesis and Application, Second Edition,Universities Press(

India) Private Limited,2010, 2013, pp 245-252.

- Ajai Kumar, Organometallic and Bioinorganic Chemistry, First

Edition,Aaryush Education, 2014, pp 7-9 to 7-11.

- Robert H. Crabtree, The Organometallic Chemistry of the

Transition Metals, Sixth Edition, John Wiley & Sons, 2014, pp 242-245.

- "Organometallic Chemistry", Spessard and Miessler

- Chem. Rev. 2012, 112, 5675 6 – 5732

- L. H. Slaugh and R. D. Mullineaux11 , J. Organometal. Chem., 1968, 13, 469

THANK

YOU…..!!!

0 Response to "Project Assignment on Hydroformylation of Alkenes and Mechanistic Investigation"

Post a Comment

Please do not enter any spam link in the comment box.